Rubber U-Channels

Extruded Rubber U-Channels for Sale

Britech is a leading supplier of extruded rubber U-channels in the U.S., with decades of experience manufacturing and distributing high-quality rubber U-channels in a wide range of rubber types, sizes, and shapes. Whether you need standard profiles or custom solutions with special colors, unique properties, or uncommon sizes, Britech offers expert support and custom mold capabilities. Our bulk rubber U-channels for sale serve as protective edges, cosmetic trims, and economical seals, and we maintain a full inventory of standard items while also accommodating large orders and custom requests with fast, reliable delivery.

Britech is one of the larger suppliers of U-Channel Extrusions in the USA today. We have been manufacturing and distributing U-Channels for over twenty years.

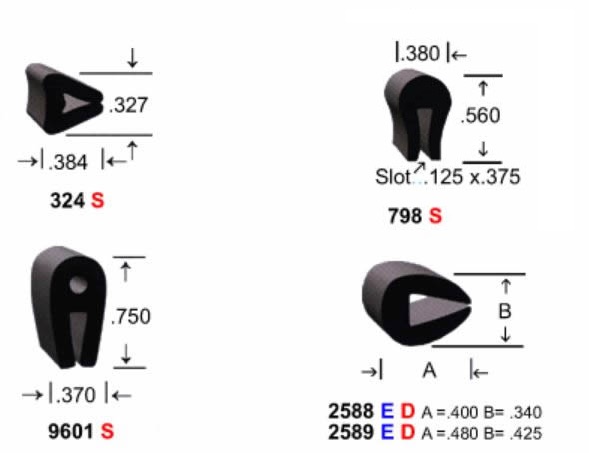

DIE IDENTIFICATION KEY: E = EPDM N = NEOPRENE NT = NITRILE D = DENSE S = SPONGE RUBBER

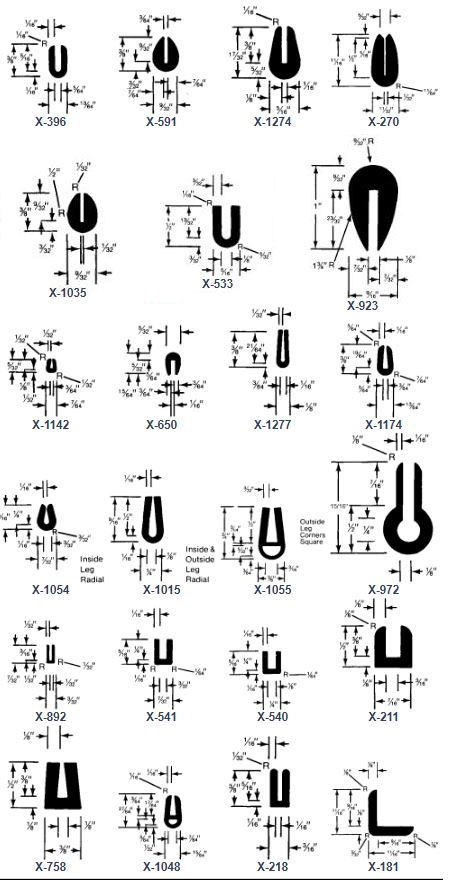

Rubber U-Channel Extrusions

Closed-cell sponge extrusions are available in standard and custom dies. EPDM, Neoprene, Nitrile, and Silicone compounds are available. These U-channel extrusions are available in continuous lengths and intricate profile shapes, but can be cut to length to meet your specifications. Our additional vulcanizing services, available upon request, offer you the option to shape the U-channel extrusion to meet the specific needs of your end installation locations around windows, doors, and other seal requirements to prevent drafts or moisture.

Benefits of Rubber Extrusions

A key factor in favor of rubber extrusions is the low die and manufacturing costs as compared to parts made from stationary molding equipment. The uses for extruded rubber are growing as industry has discovered its economic advantages. All of the extrusions shown are profiles; many are suitable to be die cut into bumpers, gaskets, seals, washers, cushions etc. They may be spliced or vulcanized endlessly to provide large diameter rings, bands, or seals. The parts shown are a small portion of the dies available. We welcome inquiries about custom designs for your requirements.

Benefits of Rubber Extrusions

A key factor in favor of rubber extrusions is the low die and manufacturing costs as compared to parts made from stationary molding equipment. The uses for extruded rubber are growing as industry has discovered its economic advantages. All of the extrusions shown are profiles; many are suitable to be die cut into bumpers, gaskets, seals, washers, cushions etc. They may be spliced or vulcanized endlessly to provide large diameter rings, bands, or seals. The parts shown are a small portion of the dies available. We welcome inquiries about custom designs for your requirements.

BRITECH U-CHANNEL FINDER

HOW TO MEASURE U-CHANNELS

Match dimensions in the figure to the left with the appropriate column in the chart below.

A = Slot Width

B = Leg Width

C = Overall Width

D = Slot Depth

E = Base Depth

F = Overall Depth

| A - Slot Width | B - Leg Width | C - Overall Width | D - Slot Depth | E - Base Depth | F - Overall Depth | Britech Part No. |

|---|---|---|---|---|---|---|

| 1/32 | 1/32 | 3/32 | 3/16 | 1/32 | 7/32 | X-892 |

| 1/32 | 1/16 | 5/32 | 5/32 | 1/32 | 3/16 | X-142 |

| 1/32 | 1/8 | 9/32 | 9/32 | 3/32 | 3/8 | X-1035 |

| 1/32 | 5/32 | 11/32 | 1/2 | 3/16 | 11/16 | X-270 |

| 3/64 | 1/32 | 7/64 | 1/8 | 1/32 | 5/32 | X-661 |

| 3/64 | 1/32 | 7/64 | 1/8 | 1/32 | 5/32 | X-1142 |

| 3/64 | 1/16 | 11/64 | 5/16 | 1/16 | 3/8 | X-200 |

| 3/64 | 1/16 | 13/64 | 19/64 | 5/64 | 3/8 | X-1174 |

| 3/64 | 7/64 | 17/64 | 9/32 | 3/32 | 3/8 | X-591 |

| 1/16 | 1/32 | 1/8 | 5/32 | 1/32 | 3/16 | X-538 |

| 1/16 | 1/32 | 1/8 | 13/64 | 1/16 | 17/64 | X-945 |

| 1/16 | 1/32 | 1/8 | 21/64 | 3/64 | 3/8 | X-1247 |

| 1/16 | 3/64 | 5/32 | 5/32 | 5/64 | 15/64 | X-650 |

| 1/16 | 1/16 | 3/16 | 1/8 | 1/8 | 1/4 | X-195 |

| 1/16 | 1/16 | 3/16 | 5/16 | 1/16 | 3/8 | X-172 |

| 1/16 | 1/16 | 3/16 | 3/8 | 1/16 | 7/16 | X-2818 |

| 1/16 | 1/8 | 5/16 | 3/8 | 5/32 | 17/32 | X-1274 |

| 5/64 | 1/16 | 13/64 | 5/16 | 1/16 | 3/8 | X-396 |

| 3/32 | 3/64 | 3/16 | 17/64 | 3/64 | 5/16 | X-379 |

| 3/32 | 1/16 | 7/32 | 1/8 | 116 | 3/16 | X-566 |

| 3/32 | 1/16 | 7/32 | 1/4 | 1/16 | 5/16 | X-1054 |

| 3/32 | 1/16 | 7/32 | 1/4 | 1/16 | 5/16 | X-541 |

| 3/32 | 5/64 | 1/4 | 7/16 | 3/16 | 5/8 | X-129 |

| 7/64 | 1/16 | 15/64 | 17/64 | * | 27/64 | X-1048 |

| 1/8 | 1/32 | 3/16 | 7/16 | 1/16 | 1/2 | X-830 |

| 1/8 | 3/64 | 7/32 | 11/64 | 3/64 | 7/32 | X-693 |

| 1/8 | 3/64 | 7/32 | 13/64 | 3/64 | 1/4 | X-299 |

| 1/8 | 1/16 | 1/4 | 1/4 | 1/16 | 5/16 | X-102 |

| 1/8 | 1/16 | 1/4 | 1/4 | 1/16 | 5/16 | X-540 |

| 1/8 | 1/16 | 1/4 | 1/2 | 1/16 | 9/16 | X-1015 |

| 1/8 | 1/16 | 1/4 | 9/32 | 1/16 | 5/8 | X-874 |

| 1/8 | 1/16 | 1/2 | 3/8 | 1/8 | 5/8 | X-972 |

| 1/8 | 3/32 | 5/16 | 9/32 | 3/32 | 3/8 | X-526 |

| 1/8 | 3/32 | 5/16 | 3/8 | 1/8 | 1/2 | X-688 |

| 1/8 | 3/32 | 5/16 | 13/32 | 3/32 | 1/2 | X-533 |

| 1/8 | 1/8 | 3/8 | 3/8 | 1/8 | 1/2 | X-758 |

| 1/8 | 7/32 | 9/16 | 23/32 | 9/32 | 1 | X-923 |

| 3/16 | 1/16 | 5/16 | 1/4 | 1/16 | 5/16 | X-1146 |

| 3/16 | 1/16 | 5/16 | 3/8 | 1/16 | 7/16 | X-341 |

| 3/16 | 3/32 | 3/8 | 1/2 | 3/64 | 3/4 | X-1055 |

| 3/16 | 1/8 | 7/16 | 3/8 | 1/8 | 1/2 | X-211 |

| 1/4 | 1/16 | 3/8 | 7/32 | 1/16 | 9/32 | X-770 |

| 1/4 | 1/16 | 3/8 | 5/16 | 1/16 | 3/8 | X-836 |

| 1/4 | 1/16 | 3/8 | 3/8 | 1/8 | 1/2 | X-190 |

| 1/4 | 1/8 | 1/2 | 1/2 | 1/8 | 5/8 | X-982 |

Contact Us

Contact us today for quotes or more information on our custom rubber and plastic extrusion or molding solutions designed to meet your specifications!

"*" indicates required fields